Pottz

in over 3 years

dust collection of your dreams

at the heart of any DC is the collector itself. this is a jet jcdc-2 2hp 1p 230v 938cfm. it does a good job but with the expansion ive done since getting it i would go with a 3hp now.

here is the back side of the router table. it pulls from the cabinet and also through the fence. works ok but could be better.

here is the hook up for the edge sander. this works pretty good.

this is what i currently have for the miter saw. collection is minimal getting maybe 50%. id like to make something that works better.

ok for the spindle sander it works good getting most of the dust.

now as most will tell you good luck collecting dust and chips from a lathe. the shroud does help with some of the fine dust though.

now for the table saw this is an older model, about 35 yrs and is not designed well for dust collection. it is what it is.

now this works very well. ive got the sander plugged into a boom arm that is hooked up to a fein dust collector that comes on as soon as i activate the sander. it can swing freely side to side and collect virtually all the dust.

this is a jet afs-1000b air filtration system. outer filter is 5 microns inner is 1 micron. air flow is 556cfm low, 702cfm med., and 1044cfm on high. if the shop is cloudy with dust on high it will cleaar the air in about 15 minutes. ive been very happy with it.

hopefully you guys will show what you use and what works well or doesn't.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

182 Replies

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

I’ve got an Oneida Supercell. It’s a high static pressure, mid/high volume DC, specifically designed for small shops. The high static pressure makes it perfect for tools with dust ports 4” or less, including all the way down to small 1.5” or 1” hoses for random original sanders and CNC and the like. Anything bigger than 4” allows for too high a loss of static pressure and decreases flow. The other advantage of high static pressure is that the DC also functions like a shop vac for clean up with a long 2.5” hose, just like a shop vac. It’ll pick up chips and dust just fine, and (because of the high static pressure) works just fine with flex hose. The Supecell does just fine with my 13” thickness planer and 8” jointer, or with my sanders…and everything in between.

For those that might be unaware, flex hose scrubs a lot of static pressure off a system owing to the corrugated interior of the flex hose. Normally this is a major issue for traditional DCs, but not for the Supercell. Of course, smooth is better, but the system will work with up to 100’ of 4” high pressure flex hose (according to their adverts). I will say that, because of the high pressure, light weight flex hose may collapse during use, so a more rigid version is supplied with the Supercell. It’s a bit unwieldy, but not terrible. Additionally, because of the high pressure, you can use smaller radius 90° turns in your ducting without issue….something that’s usually a concern with traditional DCs.

I’ve said a lot about high pressure, but it’s important to note that a high pressure system with low volume airflow (ie - a shop vac) doesn’t work well in many shop settings. This is because the high pressure dissipates quickly past the end of the intake at the tool, and usually requires a small diameter hose to be effective, meaning the dust and chips not right in front of the dust port won’t get collected. With a high volume DC, the air further away from the dust port is also drafted in, which collects the floating dust wafting around, but a low pressure, high volume system may struggle to carry away chips as the chips weigh more and require higher static pressure to collect properly…or at least a more closed-in collection area as found in cabinet saw. The Supercell provides much more volume of airflow than a shop vac, but not quite as much as a traditional large impeller DC, but with much higher pressure. This is why the Supercell has an upper limit of a 4” dust port…much more than that results in a loss of static pressure which reduces the flow. Clear as mud?

The Supercell comes in a couple different configurations, which really just relates to different sized dust bins. Although Oneida did just pre-release a new ‘Turbo’ Supercell that increases airflow volume even more. There are 3 universal motors running under the cowl of both units, which means it’s not a terribly quiet device but it’s really not bad. Those motors do generate some heat, but I haven’t noticed an issue, even during hot summer months.

While I wouldn’t call it a quiet DC, the suction sound at the end of small diameter hose is more significant than the DC itself…although I wouldn’t mind having a remote cabinet for the Supercell in a future shop. It has a built in conical separator which keeps the dust out of the motors. There’s also an internal pleated filter. An integrated filter cleaner uses a whammy bar on the side of the machine to reverse the flow of air through the filter to keep it clean. It works well.

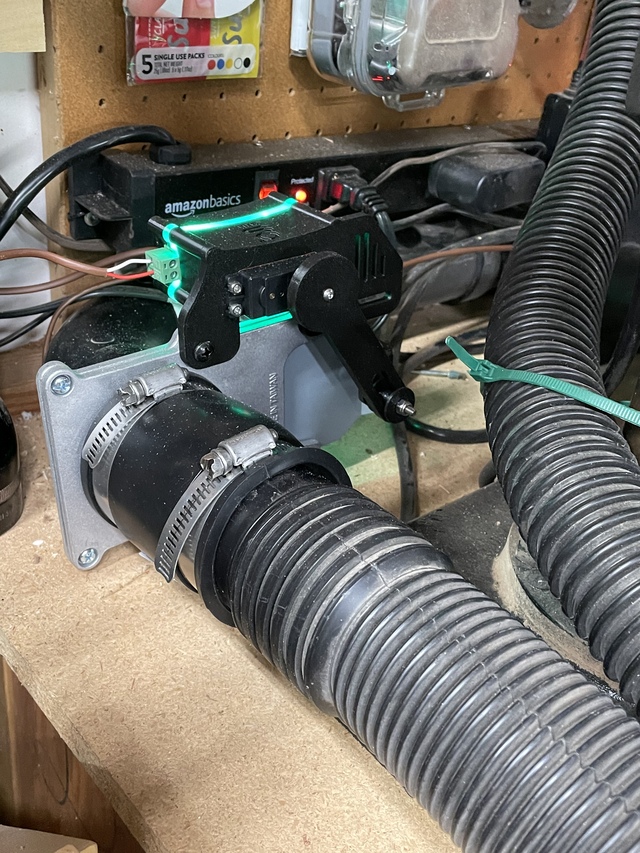

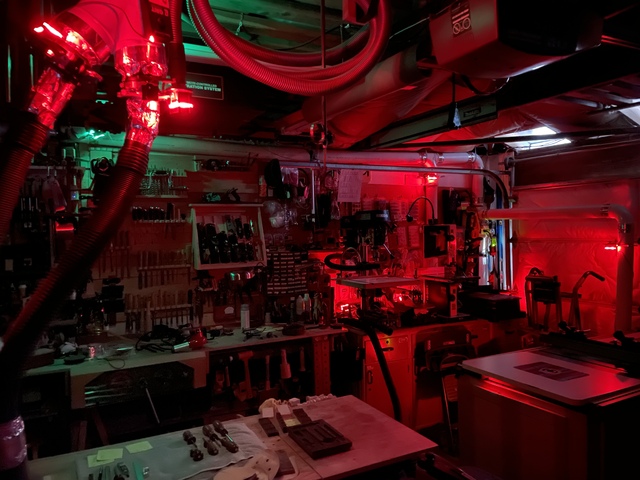

My system uses 4” S&D pipe, which is inexpensive (especially the adapters), easy to find, and just flexible enough to help with install. I seal my joints with aluminum duct tape. Of course, blast gates are a must. I use automated blast gates and tool switches from a company called GRIT automation. They use servos to drive regular run-of the-mill aluminum gates of any size…and LEDs to ID the condition of the gates. Phenomenal system. You can read more about GRIT here. I’ve had no issues with static electricity in my system. I do not ground my ducting as you can’t ground PVC, but the tools are grounded. Any images below with wire wrapped around the ducting is just low voltage, insulated wire that provides power to GRIT. I wrapped it around the pipes to keep it tidy…

I couldn’t be happier with this system, for both my larger tools and my benchtop tools. It fits my shop perfectly, is easy to use and very effective. It’s a bit more expensive than the cheap high volume DCs, but no more expensive than the high quality, high volume DCs. I’ve also been very impressed with Oneida as a company. They’re easy to talk to even in real life on a phone, and they’re happy to talk to you about your needs and offer advice, without any pressure to buy.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

I put one of these .05 micron filters on and got rid of the bag (which is a dust spreader!)

Petey

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

The biggest problem I had getting this DC setup was sealing the clear collection bag on the bottom. The bag clamp allows enough air to leak out that it was spewing a little dust into the air. The solution was to use some of the narrow stretch wrap found with the moving and packing supplies at HD. A couple of tight wraps around the top of the bag and clamp sealed it up. It will be easy to just wrap again when I empty the bag. I keep the stretch wrap in the shop to help clamp awkward shaped glue ups.

Speaking of canister filters and dust collection in general. I stumbled upon this YouTube video that used a canister filter and an inline blower for a air cleaner. The the air cleaner is at 1:18 but there are some other tips in the video that might be helpful for some.

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

...woodicted