Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Good topic Pottz-

I’ve got an Oneida Supercell. It’s a high static pressure, mid/high volume DC, specifically designed for small shops. The high static pressure makes it perfect for tools with dust ports 4” or less, including all the way down to small 1.5” or 1” hoses for random original sanders and CNC and the like. Anything bigger than 4” allows for too high a loss of static pressure and decreases flow. The other advantage of high static pressure is that the DC also functions like a shop vac for clean up with a long 2.5” hose, just like a shop vac. It’ll pick up chips and dust just fine, and (because of the high static pressure) works just fine with flex hose. The Supecell does just fine with my 13” thickness planer and 8” jointer, or with my sanders…and everything in between.

For those that might be unaware, flex hose scrubs a lot of static pressure off a system owing to the corrugated interior of the flex hose. Normally this is a major issue for traditional DCs, but not for the Supercell. Of course, smooth is better, but the system will work with up to 100’ of 4” high pressure flex hose (according to their adverts). I will say that, because of the high pressure, light weight flex hose may collapse during use, so a more rigid version is supplied with the Supercell. It’s a bit unwieldy, but not terrible. Additionally, because of the high pressure, you can use smaller radius 90° turns in your ducting without issue….something that’s usually a concern with traditional DCs.

I’ve said a lot about high pressure, but it’s important to note that a high pressure system with low volume airflow (ie - a shop vac) doesn’t work well in many shop settings. This is because the high pressure dissipates quickly past the end of the intake at the tool, and usually requires a small diameter hose to be effective, meaning the dust and chips not right in front of the dust port won’t get collected. With a high volume DC, the air further away from the dust port is also drafted in, which collects the floating dust wafting around, but a low pressure, high volume system may struggle to carry away chips as the chips weigh more and require higher static pressure to collect properly…or at least a more closed-in collection area as found in cabinet saw. The Supercell provides much more volume of airflow than a shop vac, but not quite as much as a traditional large impeller DC, but with much higher pressure. This is why the Supercell has an upper limit of a 4” dust port…much more than that results in a loss of static pressure which reduces the flow. Clear as mud?

The Supercell comes in a couple different configurations, which really just relates to different sized dust bins. Although Oneida did just pre-release a new ‘Turbo’ Supercell that increases airflow volume even more. There are 3 universal motors running under the cowl of both units, which means it’s not a terribly quiet device but it’s really not bad. Those motors do generate some heat, but I haven’t noticed an issue, even during hot summer months.

While I wouldn’t call it a quiet DC, the suction sound at the end of small diameter hose is more significant than the DC itself…although I wouldn’t mind having a remote cabinet for the Supercell in a future shop. It has a built in conical separator which keeps the dust out of the motors. There’s also an internal pleated filter. An integrated filter cleaner uses a whammy bar on the side of the machine to reverse the flow of air through the filter to keep it clean. It works well.

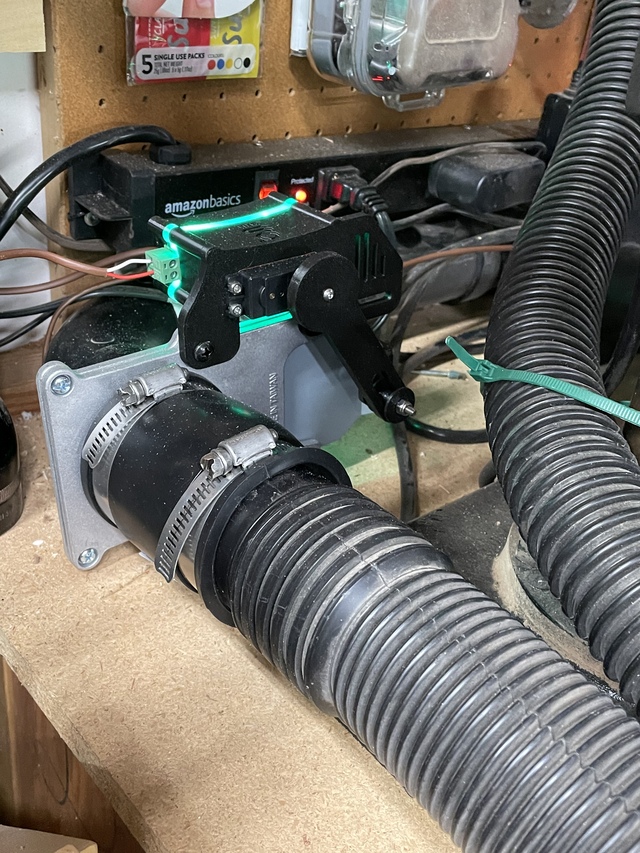

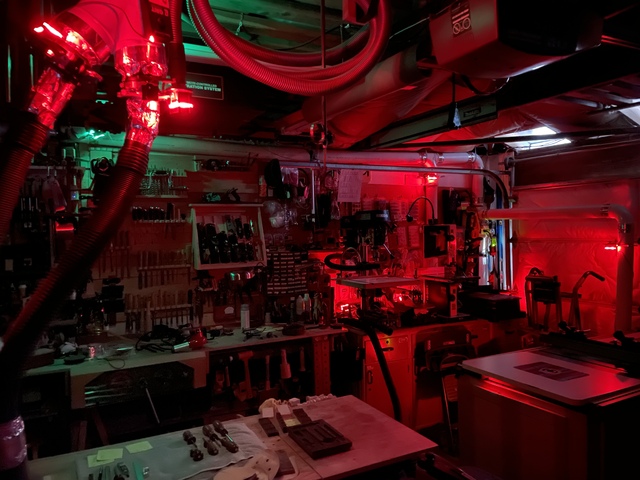

My system uses 4” S&D pipe, which is inexpensive (especially the adapters), easy to find, and just flexible enough to help with install. I seal my joints with aluminum duct tape. Of course, blast gates are a must. I use automated blast gates and tool switches from a company called GRIT automation. They use servos to drive regular run-of the-mill aluminum gates of any size…and LEDs to ID the condition of the gates. Phenomenal system. You can read more about GRIT here. I’ve had no issues with static electricity in my system. I do not ground my ducting as you can’t ground PVC, but the tools are grounded. Any images below with wire wrapped around the ducting is just low voltage, insulated wire that provides power to GRIT. I wrapped it around the pipes to keep it tidy…

I couldn’t be happier with this system, for both my larger tools and my benchtop tools. It fits my shop perfectly, is easy to use and very effective. It’s a bit more expensive than the cheap high volume DCs, but no more expensive than the high quality, high volume DCs. I’ve also been very impressed with Oneida as a company. They’re easy to talk to even in real life on a phone, and they’re happy to talk to you about your needs and offer advice, without any pressure to buy.

I’ve got an Oneida Supercell. It’s a high static pressure, mid/high volume DC, specifically designed for small shops. The high static pressure makes it perfect for tools with dust ports 4” or less, including all the way down to small 1.5” or 1” hoses for random original sanders and CNC and the like. Anything bigger than 4” allows for too high a loss of static pressure and decreases flow. The other advantage of high static pressure is that the DC also functions like a shop vac for clean up with a long 2.5” hose, just like a shop vac. It’ll pick up chips and dust just fine, and (because of the high static pressure) works just fine with flex hose. The Supecell does just fine with my 13” thickness planer and 8” jointer, or with my sanders…and everything in between.

For those that might be unaware, flex hose scrubs a lot of static pressure off a system owing to the corrugated interior of the flex hose. Normally this is a major issue for traditional DCs, but not for the Supercell. Of course, smooth is better, but the system will work with up to 100’ of 4” high pressure flex hose (according to their adverts). I will say that, because of the high pressure, light weight flex hose may collapse during use, so a more rigid version is supplied with the Supercell. It’s a bit unwieldy, but not terrible. Additionally, because of the high pressure, you can use smaller radius 90° turns in your ducting without issue….something that’s usually a concern with traditional DCs.

I’ve said a lot about high pressure, but it’s important to note that a high pressure system with low volume airflow (ie - a shop vac) doesn’t work well in many shop settings. This is because the high pressure dissipates quickly past the end of the intake at the tool, and usually requires a small diameter hose to be effective, meaning the dust and chips not right in front of the dust port won’t get collected. With a high volume DC, the air further away from the dust port is also drafted in, which collects the floating dust wafting around, but a low pressure, high volume system may struggle to carry away chips as the chips weigh more and require higher static pressure to collect properly…or at least a more closed-in collection area as found in cabinet saw. The Supercell provides much more volume of airflow than a shop vac, but not quite as much as a traditional large impeller DC, but with much higher pressure. This is why the Supercell has an upper limit of a 4” dust port…much more than that results in a loss of static pressure which reduces the flow. Clear as mud?

The Supercell comes in a couple different configurations, which really just relates to different sized dust bins. Although Oneida did just pre-release a new ‘Turbo’ Supercell that increases airflow volume even more. There are 3 universal motors running under the cowl of both units, which means it’s not a terribly quiet device but it’s really not bad. Those motors do generate some heat, but I haven’t noticed an issue, even during hot summer months.

While I wouldn’t call it a quiet DC, the suction sound at the end of small diameter hose is more significant than the DC itself…although I wouldn’t mind having a remote cabinet for the Supercell in a future shop. It has a built in conical separator which keeps the dust out of the motors. There’s also an internal pleated filter. An integrated filter cleaner uses a whammy bar on the side of the machine to reverse the flow of air through the filter to keep it clean. It works well.

My system uses 4” S&D pipe, which is inexpensive (especially the adapters), easy to find, and just flexible enough to help with install. I seal my joints with aluminum duct tape. Of course, blast gates are a must. I use automated blast gates and tool switches from a company called GRIT automation. They use servos to drive regular run-of the-mill aluminum gates of any size…and LEDs to ID the condition of the gates. Phenomenal system. You can read more about GRIT here. I’ve had no issues with static electricity in my system. I do not ground my ducting as you can’t ground PVC, but the tools are grounded. Any images below with wire wrapped around the ducting is just low voltage, insulated wire that provides power to GRIT. I wrapped it around the pipes to keep it tidy…

I couldn’t be happier with this system, for both my larger tools and my benchtop tools. It fits my shop perfectly, is easy to use and very effective. It’s a bit more expensive than the cheap high volume DCs, but no more expensive than the high quality, high volume DCs. I’ve also been very impressed with Oneida as a company. They’re easy to talk to even in real life on a phone, and they’re happy to talk to you about your needs and offer advice, without any pressure to buy.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".