Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Woodworking Blogs

view blog series

Part 2 of my Renners information pack

Not sure how you edit Blogs

so here is the picture and associated parts as described in my text

With all the last minute shaping and sanding complete, everything was ready for the final glue-up. There's not really a whole lot to show here. I...

Well, yes! You can use the Ti02 on tile and transfer a photograph over.

I personally haven't seriously tried to do this but I have seen pictures o...

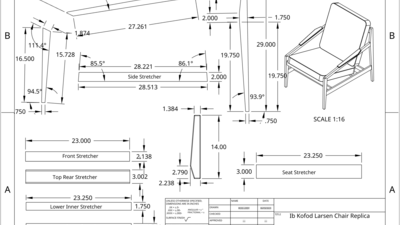

My last pair of blanks are for the armrests. I started by planing them down to 5/8" thick, which is the final thickness for rear of the armrest. ...

There were a couple things I wanted to verify before the final glue-up:

• Could I keep the paracord lacing tight enough so that it would support a ...

It's been a while since I was on here, to my old friends and everyone else, I hope you are keeping well and navigating life's challenges the best y...

Simultaneously aligning all 4 components of a side assembly gave me fits. Very slight errors in length and/or angles meant that as I sequentially ...

Most of the pressure-treated scraps from my deck skirting project were pretty narrow - around 1-1/8" wide. Most of the blanks needed for the chair...

As mentioned earlier, the armrest will fit into a 1/8" deep recess on the top of the arm. I made this router jig (from scraps) to use to cut the r...

On the heels of completing a second deck chair based on Wegner's GE-375 from pressure-treated decking, I still had some scraps left over. Enough f...

As with the other replica chairs I've made, it requires spending quite a bit of time looking at example photos from different angles in order to ma...

[01.jpg][02.jpg][03.jpg][04.jpg][05.jpg][06.jpg][07.jpg][08.jpg][09.jpg]