Buck

in about 3 years

Vacuum chuck

Thanks in advance for your help!

12 Replies

They both will work, shop vac is cheaper.

Google it , youtube it. There is a lot to know about it.

There's roosters laying chickens,and chickens laying eggs... John Prine

If your first cut is too short... Take the second cut from the longer end... LBD

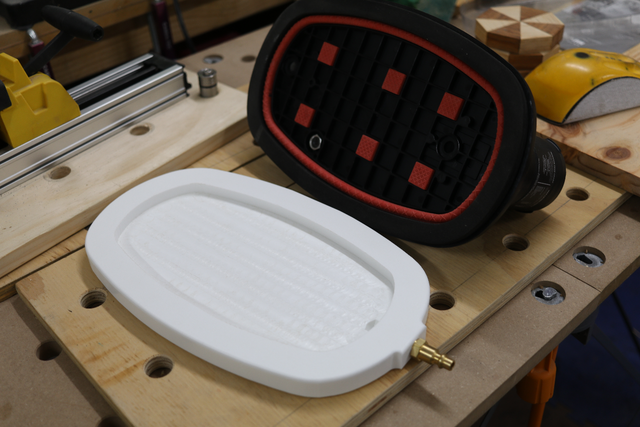

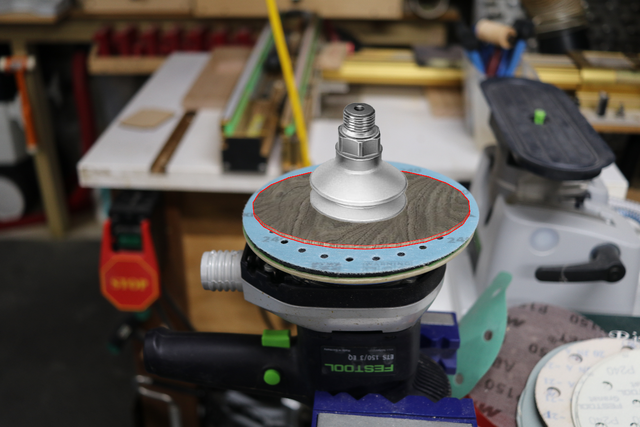

that could be adapted into a vaccum pump, and very interested in creating/extending my air vac functionality to small items... generally 75mm to 200mm pieces (square/diameter)...

Any contributing comments would be greatly appreciated as this is way above my paygrade.

If your first cut is too short... Take the second cut from the longer end... LBD

However with my recent experience with vacuum systems (Fe$tool VAC-SYS and Grabo) for holding wood, I'm very interested in smaller holding capacity.

I often sand small pieces on an upside down clamped ROS and since my dodgy left arm incident, holding onto small pieces nearly always culminates with me crawling on the floor trying to find that bloody IFO's (Identified Flying Objects).

A small diameter vacuum cup could be of assistance.

At least this thread started to make me read (UGH!) on the topic and make inquiries.

If your first cut is too short... Take the second cut from the longer end... LBD

That said, I believe it can be used, with out the Venturi, using a vacuum pump too…

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

https://www.packardwoodworks.com/110934.html

I actually ordered the wrong size thread for my lathe but I gave them a call and talked to Brad and he is taking care of switching it out for the correct size. Luckily it hadn’t shipped yet!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

for small parts... I have the vacuum covered, I just need to figure out (emails) of how to attach using my fittings (nitto tupe).

With my dodgy left arm it is hard to hold onto the small thin pieces without sanding the finger tips red.

Haven't tried double sided tape yet as if this can be set up it'd be much more versatile.

Inspired by Izzy Swan's templates.

If your first cut is too short... Take the second cut from the longer end... LBD