Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Craftisian Blogs

view blog series

Boys and Girls,

While wading through my past stuff still “unique” to LJ and some banter about scrapers here at Craftisian, I decided to migrate thi...

So I built this folding workbench a while back and the extra working space has been so good. I can pack it away by my sheet-good storage to get an...

Boys and Girls,

Centre finders got tossed up in one of the threads her at Craftisian, which prompted the excuse for migrating this across for LJ...

Got my workbench upgrades done. It didn't seem like much before I started but this did in fact take a little time.

I made 20 brackets for hinge p...

Hey Guys,

I had some questions regarding how I made gears and I thought I might as well give you the complete rundown. Perhaps the best thing to ...

In this series I want to show what different techniques I use to make my models. I appreciate comments, especially if you come up with another prop...

Glue up the sections of the top.

[20230329_165730.jpg]

Then just give it a final flatten.

[20230329_170116.jpg]

[20230329_171407.jpg]

[20230329_...

Make the wagon vice.

Chunk of willow for the screw.

[20230309_153403.jpg]

Square it up and leave it overnight in case it wants to warp at all.

[20...

So, I need a 1 1/4 inch rod for a vice screw, so make a rounding plane for it.

Get a likely looking block of wood about the right size (Yew in th...

Boys and Girls,

Just to get your attention,

[Can can.png]

Out of the thousand reasons most (including me) hate painting, I feel that decanting s...

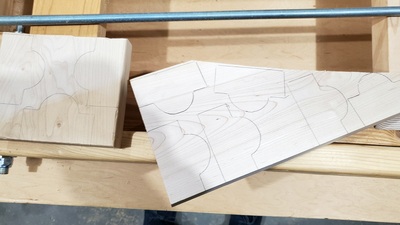

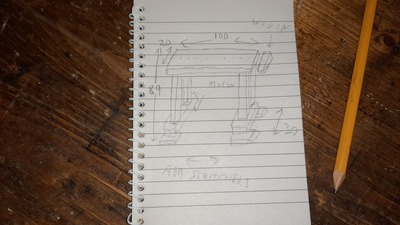

Had a bunch of 1x4’s lying around so decided to make a mini saw/workbench.

No particular plan – I've got a rough idea in my head of how I want it ...

Big box 1 x 4 lumber, so everything needs jointing.

Flatten and glue up some planks for the sides of the top.

[20230205_161734.jpg]

[20230206_1236...