Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

HokieKen

8488 posts

and

56 followers

in over 3 years

in over 3 years

How I Sharpen #4: V Tool - Part 2

This is

part 4

in a

6 part

series:

How I Sharpen

I intended to do this all in one entry but I ran into a bit of a dilemma. The tool I'm working with is an Ashley Iles 60 degree, 1/2" inch tool with a long-bent shaft. One of my most often use carving tools is another 60 degree AI V tool that's 3/8". So I probably don't really need this one but it was part of a lot on Ebay that I bought so I figured having another one with a sweep that's a little bigger can't hurt. In general, I seek Ashley Iles tools out because I really like the quality of the steel and the forging and I prefer their handles to others.

But this one is a little disappointing once I started looking at it. I ground the end flat and dyed it up and that's when I noticed the first signs of a possible issue. In my previous entry I said:

But this one is a little disappointing once I started looking at it. I ground the end flat and dyed it up and that's when I noticed the first signs of a possible issue. In my previous entry I said:

I'll add here that the quality of the forged tool is critical with a V Tool. A lower end tool will be a frustration. Here are some of the things to look for:

- Symmetry. The side legs should be a straight line, at even angles meeting at the keel.

But when I looked at the end of this tool:

I noted that the left leg in the photo is a good deal thicker than the right leg and the right leg tapers down towards the top. Hmmm. In theory, this will mean that the tool will want to pull to the right when carving. But I decided to go ahead and start working it in and see what happens.

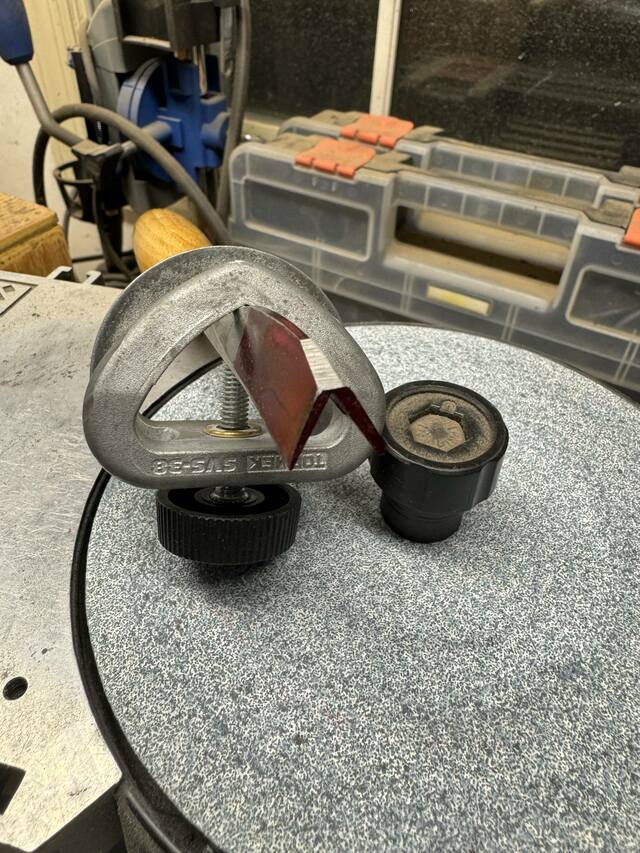

In the previous entry, I reviewed the geometry of the tool and the three main bevels, the two side legs and the keel. I like to start by setting the keel bevel first. So I clamped the tool up in my Tormek jig so that it was a little shallower than the angle I prefer to carve at. When I did the gouge in an earlier entry, I set it at the finished angle I wanted so why shallower here? Because I have a good deal more steel to remove from the keel on this tool than on a gouge. As I remove steel, the bevel will drop the end of the tool down and I'll end up with a higher grip angle than I started with. I don't measure these angles, I just do it by feel. Once I get the bevel roughed in, I'll check it and make any adjustment necessary.

I start with 80 grit on the Work Sharp and grind a flat bevel on the bottom until I'm about 1/32" or so from the apex of the internal bend radius on the tool.

It is important here to make sure you keep the keel bevel flat and symmetric here. If you skew to one side or the other, you'll end up with a tool that pulls to one side or with a non-flat bevel on the keel which makes it harder to maintain your tool position when carving. One of the things I really like about the Work Sharp is that it does form a flat bevel.

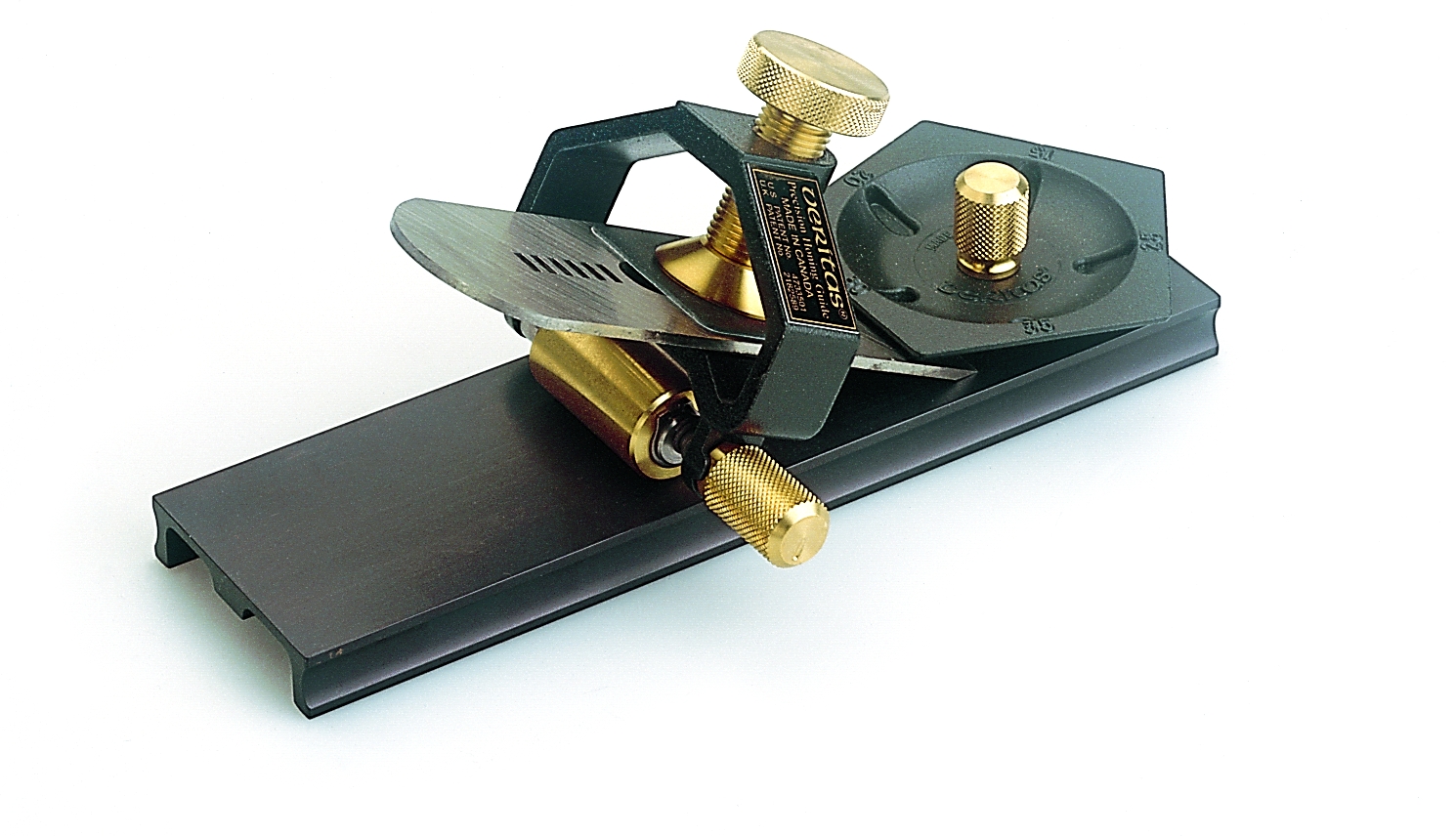

FWIW, you could sharpen this tool using a top clamping honing jig like the Veritas:

You just have to reset the tool for each bevel but they are all 3 flat, straight bevels. And with a guide like this you take the human error out of the equation. I just prefer the Tormek jig because I can set the tool once and do the whole tool without removing it. But I also have to be very careful to hold it right since it rotates on the bar and I could easily end up with rounded or multifaceted bevels if I'm not conscientious of how I'm holding it.

Once I have the keel bevel roughed in, I am ready to move to the chisel bevels on the two legs. I checked to make sure the angle my tool is at now is comfortable for use and then rotate it so one of the legs sets flat on the bar. I will keep the chisel bevels at the same setting as the keel in my jig BUT that means they may be at a different angle. Depending on where the keel is in relation to the axis of the handle compared to the legs, the bevel angle may differ. But the variance will be minor and when carving, I'm always holding this tool with the keel down so it really doesn't make any practical difference.

So I roughed in the two side bevels so there is about 1/32" of the flat face on the end left:

Yowza! In the first pic you can see that the leg on the left is of pretty constant thickness but the leg on the right tapers way down at the top. And in the second pic, you can see that the bevel on the thicker leg sweeps back further at the keel and at the top side it's shorter than the bottom but not by a lot. However on the thinner leg on the left, the bevel is at an angle and doesn't go back very far at all at the top of the leg.

So I stopped my work at that point and I'll stop this blog here. I haven't decided yet how to fix this tool. The best option is probably to just grind the thicker leg down so it matches the thinner one. The only other option is to fudge the bevel angle on the thick one but I'm afraid it won't cut satisfactorily if I do that. This was a used tool and could have been a "seconds" or a previous owner may have ground one leg down for some unknown reason. This is far below the usual quality of forging for Ashley Iles in my experience. In other cases, I may just toss it since I didn't pay a lot for it and it's not a tool I really need but since I'm doing this blog series anyway, I guess it's a good opportunity to do a little extra work.

Until the next one.

21 Comments

Nice write up. Thanks!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

If you were to just take a half-inch or so off the end, does it even out, or is it asymmetric all the way up? That would be the deciding factor for me. I could live with a shorter tool.

May you have the day you deserve!

Nope, it’s assymetric olong the full length Dave. That wpuld be nice if it were that simple.

Hmm. I think I would likely set it aside while I “figured it out.” Which probably wouldn’t ever happen. Oh well, at least you didn’t pay a lot for it.

May you have the day you deserve!

Can you grind away some of the thickness form the fat side, at least up an inch or two? Or will the "V" center being moved over cause other grief?

Yeah Splint, I think that’s the way to go. Both legs are about the same at the bottom but the thinner one tapers significantly towards the top. I think grinding the thick leg to have the same taper is the best way to go. The tops of the cutting edges will be weaker than the bottom but the whole edge isn’t ever really engaged anyway. It may alter the 60 degree bend angle but that not an issue either.

Following along keenly. Ive got a jacked up v tool thats vexed me. Good visual insight here. Thats some good splainin you do.

Best for me here are the illustrations, really great work to cleanly show the what's what and the what for.

Out of all the AI carving tools I've commissioned, I've probably had about 10 gouges where one side was slightly fatter than the other. It happens, although I don't think any of mine have been as bad as that v-tool appears to be.

Andy -- Old Chinese proverb say: If you think something can't be done, don't interrupt man who is doing it.

Yeah with the few I have they have always been excellent quality. This is the first one that will need more than just some edge work to get it commissioned. With a used tool, it’s hard to tell what’s happened to it in the past though.

I bought some AI tools, and the #2 left and right bent skews were different widths than advertised. I don't consider that as any sort of failure on their part, since the tools are hand made. Back when I was working for a living, I'd rake the machine shop over the coals if they did that on one of my designs, though. The carving tools I bought from AI were ready to use right out of the package.

The Other Steven

AI tools do come with a good edge IME DL but the angles are too high to be comfortable for me so I still regrind them.

Speaking of bent skews… I ordered a pair of L/R bent skewed shallow gouges by Pfeil from Woodcraft in January of ‘21. I got the left skewed one last spring. The right skew is still on backorder!

Speaking of bent skews… I ordered a pair of L/R bent skewed shallow gouges by Pfeil from Woodcraft in January of ‘21. I got the left skewed one last spring. The right skew is still on backorder!

Do you ever wonder Kenny why carving tool manufacturers put a 25 degree bevel on their tools when carvers want the bevel to be 20 degrees or less. It would sure save a lot of time and money if they came with 20 degree bevels.

Also, regarding your back-ordered Pfeil bent skew, this is exactly why I went on a mission at the beginning of lockdown to acquire all the carving tools I'll ever need. Whilst I agree with the sentiment that you should buy the tools as you need them according to what you want to carve next, I found it impossible to follow that sentiment. The way carving tool manufacturers work is they make small batches of a certain tools at any given time, so if you want a 1/2" Sweep 3 straight gouge and they are out of stock, it can be a couple of years before they set up to make that tool again. I decided to be proactive and compiled a spreadsheet of all the tools I thought I'd need and every two weeks, I trawl Ahsley Iles website and buy any tools that they have that are on my list. I know many people haven't always got the cash to hand to follow this approach, but I can't see any other way to do it really. It shouldn't be necessary to do this, but yet it is.

Also, regarding your back-ordered Pfeil bent skew, this is exactly why I went on a mission at the beginning of lockdown to acquire all the carving tools I'll ever need. Whilst I agree with the sentiment that you should buy the tools as you need them according to what you want to carve next, I found it impossible to follow that sentiment. The way carving tool manufacturers work is they make small batches of a certain tools at any given time, so if you want a 1/2" Sweep 3 straight gouge and they are out of stock, it can be a couple of years before they set up to make that tool again. I decided to be proactive and compiled a spreadsheet of all the tools I thought I'd need and every two weeks, I trawl Ahsley Iles website and buy any tools that they have that are on my list. I know many people haven't always got the cash to hand to follow this approach, but I can't see any other way to do it really. It shouldn't be necessary to do this, but yet it is.

Andy -- Old Chinese proverb say: If you think something can't be done, don't interrupt man who is doing it.

Yeah Andy, it would be nice if they put a 20 degree bevel on them instead of 25. If they'd drop it to 15 I'd be tickled pink but I probably like my bevels a little shallower than most. I don't think I have any that I've commissioned myself that are steeper than 20 though and if that was the factory grind, I wouldn't have to remove so much material to drop it another 3-5 degrees. Hell, I might even adjust my muscle memory to just use the 20 degrees if it meant I could use the tool out of the box.

I sort of followed the same approach as you in that I amassed a bunch of carving tools that I thought I "might" need rather than waiting until I "do" need it. I did manage to get a couple of AI tools during the beginning of the pandemic by buying them directly but since I'm on the other side of the pond, I couldn't afford the international shipping to do it with my whole wishlist. US distributors of AI have spotty inventory when I check so it looks like AI is at least trying to supply them when possible. But there's a lot more "OUT OF INVENTORY" labels than there are "ADD TO CART"s when I browse US sellers. And I pretty much have the basics covered so usually the tools I'm after are ones probably on their lower production priorities. I have been eyeballing a 45 degree V tool lately and TFWW has several sizes in stock but $56 +shipping usd is hard to swallow. If I lived over there and could buy direct for $42 and not have to pay international costs, I would probably already have it. Seems silly to quibble over $14 I guess but when you do that on 15 or 20 different tools over the course of a couple years, it becomes a little more significant. So I regularly check ebay and just take what comes at a good price.

A lot of the tools I bought when I started getting a little more serious about carving are made by Schaaf. I bought the twelve piece set but have only commissioned 4 or 5 of them so far. The rest are either redundant with tools I already have or are tools I just haven't needed yet. The set was only $95 when I bought it and even if I never use any more of them I feel like I got a bargain. I think the tools are very comparable to Pfeil in terms of construction and steel quality. They are less refined but for half the price, I don't mind. I will say the edges were purely rough ground. They could not be used out of the box so if one doesn't intend to immediately commission the edges, I wouldn't recommend them. But once I ground and sharpened them to suit me, I have no complaints with the quality of the steel. With the exception of one I have commissioned that had the tool out of line with the handle, I have no complaints about the construction either. The forging is good. Some have rough edges but some sandpaper smooths it up quickly. And to their credit, I e-mailed them a photo of the tool that was misaligned and they sent me a replacement immediately no questions asked. So if anyone's looking for a good set of quality tools that won't break the bank, I highly recommend them with the caveat that you WILL have to sharpen them. IIRC, there was an option to add "hand sharpening" when you bought direct from them but now when I click on the "premium set" link, it returns a bad page so they may not offer that anymore. I will also say, they do state that the tools come ground but not sharpened so they aren't trying to pull the wool over anyone's eyes.

Anyway, I agree with you Andy, in the current market condition it's a good idea to buy the tools you want when you can if you can afford to. Otherwise you're liable to get in a spot where you order a tool when you "need" it and still be waiting 3 years later...

I sort of followed the same approach as you in that I amassed a bunch of carving tools that I thought I "might" need rather than waiting until I "do" need it. I did manage to get a couple of AI tools during the beginning of the pandemic by buying them directly but since I'm on the other side of the pond, I couldn't afford the international shipping to do it with my whole wishlist. US distributors of AI have spotty inventory when I check so it looks like AI is at least trying to supply them when possible. But there's a lot more "OUT OF INVENTORY" labels than there are "ADD TO CART"s when I browse US sellers. And I pretty much have the basics covered so usually the tools I'm after are ones probably on their lower production priorities. I have been eyeballing a 45 degree V tool lately and TFWW has several sizes in stock but $56 +shipping usd is hard to swallow. If I lived over there and could buy direct for $42 and not have to pay international costs, I would probably already have it. Seems silly to quibble over $14 I guess but when you do that on 15 or 20 different tools over the course of a couple years, it becomes a little more significant. So I regularly check ebay and just take what comes at a good price.

A lot of the tools I bought when I started getting a little more serious about carving are made by Schaaf. I bought the twelve piece set but have only commissioned 4 or 5 of them so far. The rest are either redundant with tools I already have or are tools I just haven't needed yet. The set was only $95 when I bought it and even if I never use any more of them I feel like I got a bargain. I think the tools are very comparable to Pfeil in terms of construction and steel quality. They are less refined but for half the price, I don't mind. I will say the edges were purely rough ground. They could not be used out of the box so if one doesn't intend to immediately commission the edges, I wouldn't recommend them. But once I ground and sharpened them to suit me, I have no complaints with the quality of the steel. With the exception of one I have commissioned that had the tool out of line with the handle, I have no complaints about the construction either. The forging is good. Some have rough edges but some sandpaper smooths it up quickly. And to their credit, I e-mailed them a photo of the tool that was misaligned and they sent me a replacement immediately no questions asked. So if anyone's looking for a good set of quality tools that won't break the bank, I highly recommend them with the caveat that you WILL have to sharpen them. IIRC, there was an option to add "hand sharpening" when you bought direct from them but now when I click on the "premium set" link, it returns a bad page so they may not offer that anymore. I will also say, they do state that the tools come ground but not sharpened so they aren't trying to pull the wool over anyone's eyes.

Anyway, I agree with you Andy, in the current market condition it's a good idea to buy the tools you want when you can if you can afford to. Otherwise you're liable to get in a spot where you order a tool when you "need" it and still be waiting 3 years later...

I’ve found this true with my Pfeil gouges (which are really all I have). I bought a heavy handful of them upfront, based on what I consider pretty extensive research on the most used gouges for what I wanted to do. There are a couple more I’d like to add, but I can’t ever find them when I swing by woodcraft and I don’t really ‘need’ them so I wait…

I could certainly get behind a planned large purchase of gouges up front if there was good guidance on what to buy, but I think you run into problems with buying what you ‘think’ you need without the experience to tell you so. I’ve got a small handful of gouges I routinely reach for as part of everyday use (ie- not a carving specific project). Many of the others sit idle most all the time.

I also lack the artistic ability to put many gouges to proper use. My hack version of carving is limited to small design work usually. I’d probably get a little better if I did more, or course. But then, I often immerse myself in a discipline (and the associated tools) to learn about it and get a basic, functional level of skill to add it to my overall repertoire. Whether I continue to learn and refine that skill set usually has to do with the projects I decide to work on…

I could certainly get behind a planned large purchase of gouges up front if there was good guidance on what to buy, but I think you run into problems with buying what you ‘think’ you need without the experience to tell you so. I’ve got a small handful of gouges I routinely reach for as part of everyday use (ie- not a carving specific project). Many of the others sit idle most all the time.

I also lack the artistic ability to put many gouges to proper use. My hack version of carving is limited to small design work usually. I’d probably get a little better if I did more, or course. But then, I often immerse myself in a discipline (and the associated tools) to learn about it and get a basic, functional level of skill to add it to my overall repertoire. Whether I continue to learn and refine that skill set usually has to do with the projects I decide to work on…

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

For those who aren’t aware, and who have more time than money, the Mountain Woodcarvers Clearance Sale has some awfully good prices on a few tools. They are not sharpened, but they’re good steel. The selection is small, but they have at least one of every curve, and I’ve been happy with all of the gouges I’ve bought from them (once I sharpened them up). Sorry, Kenny, but the only V is a 70 degree.

I also got a couple dozen blanks from them on a previous closeout sale. They’re blanks for a #1x13mm gouge (i.e. flat) but they’re thick enough blanks that I made a #5x8mm gouge from one by grinding it carefully. I don’t see any of the blanks there now but if someone wants to try their hand, I could probably swap a couple for something or other. You couldn’t make any of the deeper gouges from them, but for shallow gouges, these would work.

I also got a couple dozen blanks from them on a previous closeout sale. They’re blanks for a #1x13mm gouge (i.e. flat) but they’re thick enough blanks that I made a #5x8mm gouge from one by grinding it carefully. I don’t see any of the blanks there now but if someone wants to try their hand, I could probably swap a couple for something or other. You couldn’t make any of the deeper gouges from them, but for shallow gouges, these would work.

May you have the day you deserve!

I have a few of their closeout tools too Dave. I believe they are leftover stock from Sculpture House. They are good steel and good forging but definitely have no edge at all. And on the ones I bought, the handles were crap. But the prices are good enough that even if they were unhandled it would have been a good deal. Most of the common sizes are sold out on a lot of the styles but there are still definitely some useful tools left and you can get three or four for the price of one Pfeil or Ashley Iles.

Ryan I hear ya. I’m kinda the same. Sometimes my carving stuff will sit untouched for months at a time so I definitely don’t put in the time I would need to ever really get proficient. Luckily it’s not a skill that seems to deteriorate for me. Usually I can pick up a project after a couple months and fall right back into the swing😁

Those are some good prices!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

All of the blanks I got are unhandled, Kenny. And yeah, no edge at all would be a kind description. As in, not even a good edge for a blunt scraper, Bill Carter style (he has a chisel with a flat-ground end for some of his work shaping wedges)

May you have the day you deserve!