Bentlyj

in almost 12 years

Typical Stuff In The Shop #16: Solid Surface Top

This is

part 16

in a

18 part

series:

Typical Stuff In The Shop

I'm building a small melamine kitchen for my sales rep at the lumber store.

Along with the cabinets I'm going to make a solid surface counter top with an undermount sink.

I've done quit a few tops in my past, but I haven't done any solid surface work for about 15 years or so. I'm feeling a little rusty.

I'm just getting started on the top. So far I have only marked and cut out the hole for the sink.

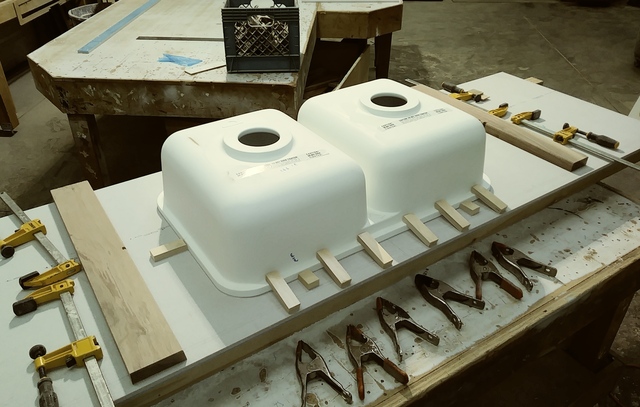

Here is the top and the sink.

I think tomorrow I am going to glue the sink on and the build up for the front edge.

I rough cut the opening and then finished the hole with the router. Jig saw can leave micro cracks that later on down the road can start a crack, so I'm making sure to smooth the edge real good.

I wont be making the bowl flush with the top. I'm going to leave the top hanging over the bowl 3/8", basically to save some work.

Figuring out how to do something you have never done is what makes a good challenge.

16 Comments

She said she doesn't use her kitchen much, just trying to update the old golden oak cabinets that are falling apart.

It's a textured dark woodgrain exterior with grey interiors. I'll post some pics tomorrow. We ordered doors which won't be here for a few more weeks yet.

Figuring out how to do something you have never done is what makes a good challenge.

Started with hot gluing blocks to keep the sink where I want it.

Next I prepare all the pieces parts to clamp it in place,

To prep the surfaces I sanded the surface with 80 grit block and cleaned up with acetone.

Next was to get the adhesive ready. Pulled out my old glue gun, purged the adhesive before putting on the mixing tip, then purged it again. No pictures of the adhesive being put on the sink rim, but I put a small bead on the inside hoping for minimal squeeze out, and a normal bead around the outside, then turned it upside down and put it in place and applied the clamps.

I also ended up sliding some blocks underneath the side to force the top up to the sink better. I think my side boards were only applying most of the pressure to the ends.

Now I wait and see, cross my fingers that the inside won't take much clean up.

Once it's cured I will go on to the front build up. Material is 1/2" thick, so I will add to layers to make the front 1 1/2"

Figuring out how to do something you have never done is what makes a good challenge.

We ordered doors which won't be here for a few more weeks yet.

L/W

“Those who would give up essential Liberty, to purchase a little temporary Safety, deserve neither Liberty nor Safety.” Benjamin Franklin

I did build the cabinets.

She gets a deal on the doors from work because they distribute their product. (And I don't have to mess with them.)

Tops just need a quick buff on the front edges and they will be done.

Figuring out how to do something you have never done is what makes a good challenge.

You always find something complimentary to say, I appreciate that.

If you look at the picture with the acetone, you can see the bevel on the edge of the blocks to guide it down. (Bevel is about 3/4 of the block then flat on the end.)

Solid surface is just like wood. All the same tools and easy to do. Just harder, and makes a mess like mdf, except the particles fall to the ground quicker.

I had thought it would be more interesting, since nobody ever shows it.

Figuring out how to do something you have never done is what makes a good challenge.

Those inside radius corners aren't as easy as they look. Only one shot to get those right

I'm using 2 on her job, and keeping the other 3 for myself. Maybe out of style, but new counter tops for 30 bucks sounds like a win win for me.

Figuring out how to do something you have never done is what makes a good challenge.

L/W

“Those who would give up essential Liberty, to purchase a little temporary Safety, deserve neither Liberty nor Safety.” Benjamin Franklin

Figuring out how to do something you have never done is what makes a good challenge.

Figuring out how to do something you have never done is what makes a good challenge.

Your tips, and applications do have some universal applications though in most cases. I enjoyed reading through it.

Thanks for sharing.