Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

awsum55

1041 posts

and

24 followers

in about 3 years

in about 3 years

An inexpensive way to get into open segmented turning.

I've never done a blog before and I don't know if this is the right way to do it, so here goes.

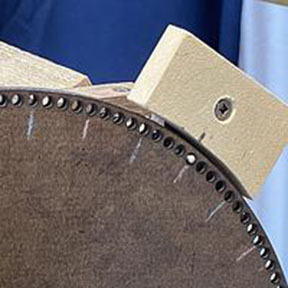

As my friend LBD would say “Hello boys and girls”. Here is a description of what I did to make this index wheel and the mechanism to operate it. This is an indexing jig I made for open segmented turnings on my lathe. I used pressboard/masonite for the wheel and cut the holes with my laser. Then I cobbled together a mechanism to register the wheel.

As my friend LBD would say “Hello boys and girls”. Here is a description of what I did to make this index wheel and the mechanism to operate it. This is an indexing jig I made for open segmented turnings on my lathe. I used pressboard/masonite for the wheel and cut the holes with my laser. Then I cobbled together a mechanism to register the wheel.

I used the program Lightburn to layout the wheel (144 holes) with a 1” bore to fit my spindle. It fits between the chuck and the shoulder on the spindle, and that keeps it pinned. I mark the wheel with chalk to guide me through the process.

I must confess, I’m a squirrel and save just about everything because when I have an idea, I don’t want to wait or go to the store.

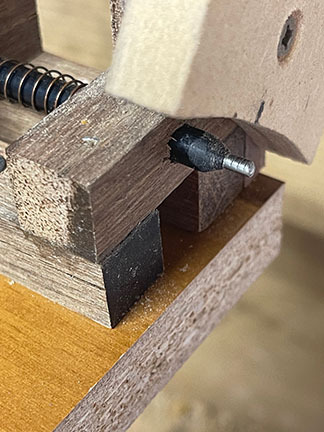

I found a hollow piece of fiberglass that was the right diameter to fit inside a spring I had, probably from a ballpoint pen.

I drilled a perpendicular hole through the fiberglass dowel and glued in a finish nail that I cut to size and rounded over the ends.

Another section of finish nail was used for the end of the dowel to register in the holes on the wheel.

For times when I need to be able to rotate the chuck without having to worry about the pin stopping the wheel, I cut a slot in a piece of wood and attached it to the unit with a staple through a shoelace. I just pull the handle back and place the wood on the plunger to prevent it from extending out far enough to engage the wheel.

Once it was all set up I used a few scraps of wood to make something I could use to see where the pin was lining up from the chuck side of the lathe.

I drilled and tapped a 1/4" hole in the top of my lathe and drilled another small hole for a brass pin I used to keep the unit from rotating out of position.

I held the unit in place with a thumb screw I welded up.

Here is a short video of how it all works.

.................. John D....................

3 Comments

Your off to a good start, interesting set up and I can see where it would come in handy for segments.

Main Street to the Mountains

👍👍👍,🦆... Thanks.

If your first cut is too short... Take the second cut from the longer end... LBD

Great job (three exclamation points)

Would be great for router work on the lathe too (flutes and such), which is why I bought my commercial version. Let your imagination run wild.

Would be great for router work on the lathe too (flutes and such), which is why I bought my commercial version. Let your imagination run wild.